Void Fill Packaging

The Ultimate Guide to Void Fill Packaging: Protection and Efficiency in Every Package

Void fill packaging is a critical component in the delivery process of products across various sectors. Its primary function is to fill the empty spaces or ‘voids’ in packaging boxes, thus preventing the product from moving or shifting during transportation. This ensures that the product stays secure and undamaged, reaching the customer in the same condition it left the warehouse.

In an increasingly competitive market, this protection is not just about preventing damage, but also about maintaining brand reputation and customer satisfaction. A damaged product can lead to returns, negative reviews, and loss of customer trust. Thus, void fill packaging is an essential part of a successful eCommerce strategy.

In This Article

The Role of Void Fill Packaging in Secure and Efficient Product Delivery

Efficient product delivery is more than just getting a product from point A to point B. It involves ensuring that the product is delivered on time, in pristine condition, and at the lowest possible cost. Void fill packaging plays a significant role in achieving these objectives.

By filling up the empty spaces in the packaging, void fill materials prevent the product from moving around in the box, reducing the risk of damage during transit. This not only saves costs associated with product returns and replacements but also helps maintain a positive brand image.

Additionally, certain types of void fill packaging, like air pillows or packing peanuts, are lightweight, thus adding minimal weight to the package. This can significantly reduce shipping costs, making product delivery more efficient.

In summary, void fill packaging is a crucial element in the logistics and supply chain process, contributing to secure, efficient, and cost-effective product delivery. The subsequent sections of this guide will delve deeper into different types of void fill packaging, their applications, and how to choose the right one for your specific needs.

Understanding Different Types of Void Fill Packaging

Air Pillows: Lightweight and Effective Void Filling Solution

Air pillows are a modern and efficient void fill solution. They are essentially plastic bags inflated with air, providing a cushioning effect for products during transit. Their lightweight nature means they add minimal weight to packages, keeping shipping costs low. They are also space-efficient as they can be inflated on demand, reducing storage space requirements.

Packing Peanuts: Classic and Affordable Void Fill Material

Packing peanuts, also known as loose fill, are a classic choice for void fill packaging. They are small, lightweight pieces of polystyrene that provide excellent cushioning and protection for products. They are particularly useful for filling irregular spaces in packages. Despite being somewhat messy and not the most eco-friendly option, they remain popular due to their affordability and effectiveness.

Bubble Wrap: Popular and Versatile Packaging Material

Bubble wrap is perhaps the most well-known type of void fill packaging. It consists of plastic sheets featuring numerous tiny air-filled bubbles. These bubbles provide excellent shock absorption, protecting products from impact and vibration during shipping. Bubble wrap is versatile and can be used for a wide range of products, from fragile glassware to heavy industrial parts.

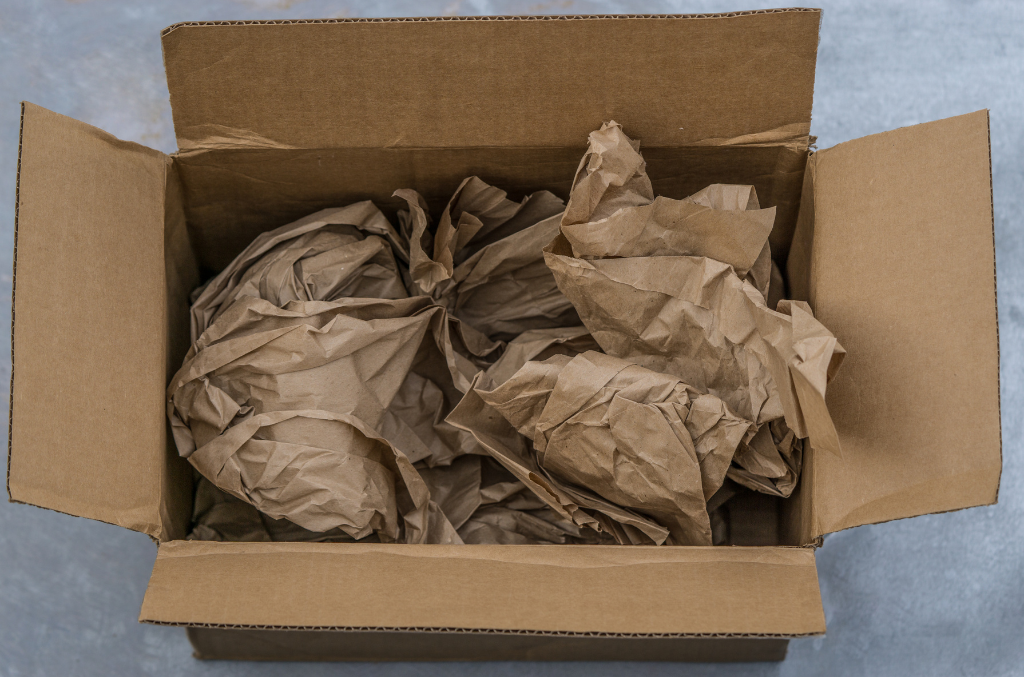

Paper: Eco-Friendly and Cost-Effective Void Fill Solution

Paper void fill is an increasingly popular choice, especially among businesses seeking to reduce their environmental impact. Made from recycled paper, this void fill solution is biodegradable and easily recyclable. Paper can be crumpled or configured into various shapes to fill voids effectively. Despite being heavier than some other options, it remains a cost-effective choice for many businesses.

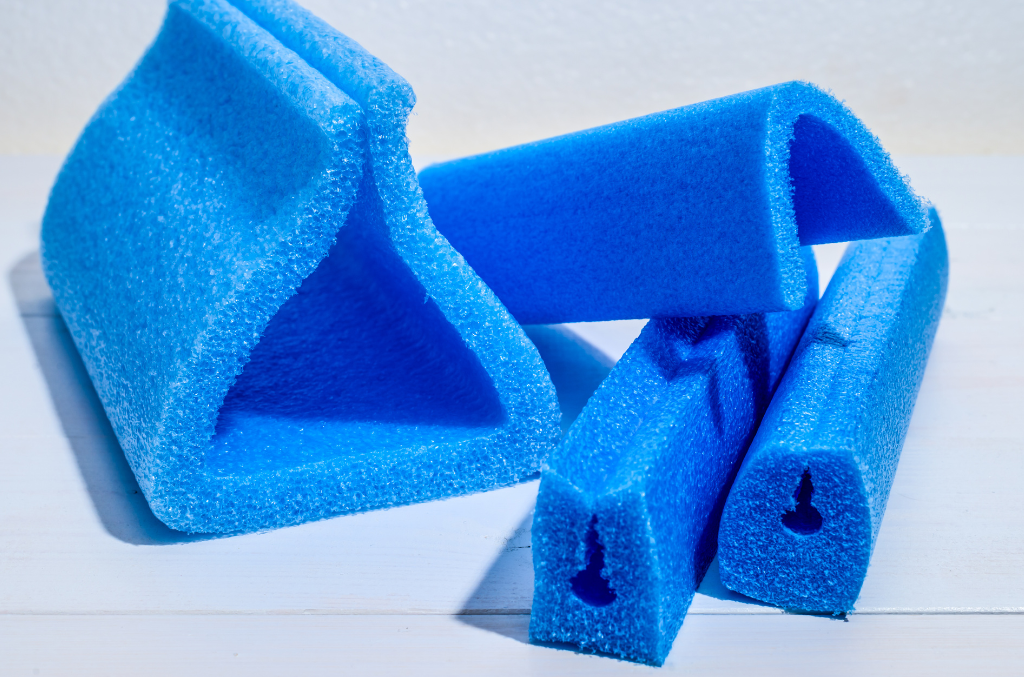

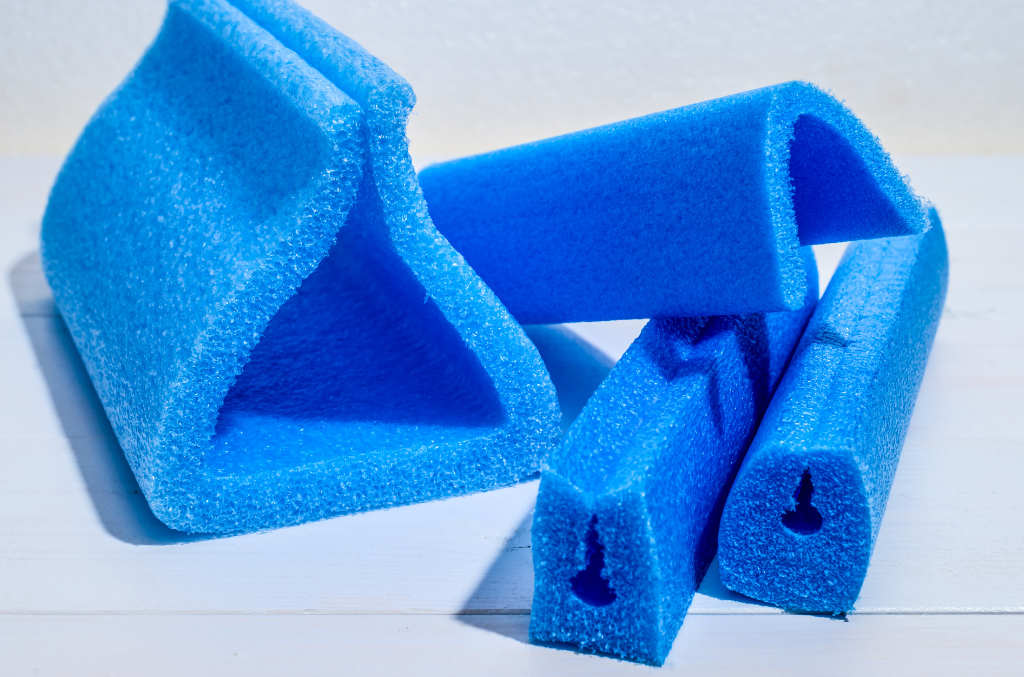

Foam: High-Protection, High-Cushioning Void Fill Choice

Foam void fill provides superior protection and cushioning for fragile and high-value items. It is often used in the form of foam-in-place or molded foam, where it expands to fill voids and conforms to the shape of the product. While more expensive and less environmentally friendly than other options, foam is ideal for certain applications where maximum protection is required.

In conclusion, the choice of void fill packaging depends on various factors such as the nature of the product, shipping conditions, cost considerations, and environmental impact. The following sections of this guide will help you understand these factors and make an informed decision about the best void fill solution for your business.

The Science Behind Void Fill Packaging

The Physics of Product Protection: Cushioning and Fill

The fundamental principle behind void fill packaging lies in the science of physics – specifically, the concept of cushioning. Void fill materials act as a cushion, absorbing shocks, impacts, and vibrations that a package might experience during transit. By filling the ‘void’ or empty space within a package, these materials prevent the product from moving, thereby minimizing potential damage.

The effectiveness of a void fill material in cushioning a product is determined by several factors such as its density, thickness, and the amount of air or space within the material. For instance, air pillows and bubble wrap have numerous small air-filled pockets that provide excellent shock absorption, while packing peanuts and paper fill the voids completely, providing both cushioning and fill.

How Different Void Fill Materials React to Pressure

Different void fill materials react differently to pressure and impact. Air pillows and bubble wrap compress under pressure, with the air inside the pockets acting as a shock absorber. Once the pressure is released, they bounce back to their original shape, ready to absorb the next impact.

Packing peanuts, on the other hand, can shift within the package to accommodate pressure, filling up spaces around the product and providing cushioning. Paper void fill works similarly, with the crumpled or configured paper providing both fill and cushioning.

Foam void fill reacts to pressure by conforming to the shape of the product. Foam-in-place, for instance, expands and hardens around the product, creating a custom cushion that offers high-level protection.

Understanding these different reactions to pressure can help businesses choose the right void fill material based on the fragility of their products and the potential risks during shipping. The subsequent sections of this guide will discuss these considerations in more detail to help you make the right choice.

Industry Applications of Void Fill Packaging

Void Fill Packaging in Manufacturing/Distribution

In the manufacturing and distribution industry, void fill packaging is crucial for ensuring the safe delivery of products. Whether it’s small electronic components, automotive parts, or large machinery, void fill materials like foam, air pillows, or bubble wrap can provide the necessary protection and cushioning during transit.

Healthcare Industry: Safe Transport of Sensitive Equipment and Supplies

The healthcare industry often needs to transport sensitive equipment, medical supplies, and pharmaceuticals. These items require high levels of protection to prevent damage and contamination. Foam-in-place is commonly used in this sector due to its ability to form a custom fit around products, offering superior protection. Eco-friendly options like paper void fill are also popular for shipping less fragile items like bandages or disposable medical wear.

Education Sector: Protecting Educational Materials and Equipment

In the education sector, void fill packaging is used to safeguard various educational materials and equipment. From textbooks and stationery to lab equipment and electronics, different types of void fill materials are utilized depending on the item’s fragility. Bubble wrap and packing peanuts, for instance, are commonly used for their versatility and affordability.

Building Services: Ensuring Safe Delivery of Tools and Materials

For building services, ensuring the safe delivery of tools and construction materials is crucial. Heavy-duty void fill materials like foam are often used to protect power tools and other heavy equipment, while lightweight options like air pillows or paper can be used for smaller, less fragile items.

In conclusion, the application of void fill packaging varies across industries, depending on the nature of the products being shipped and their specific protection requirements. By understanding these applications, businesses can choose the most suitable void fill solutions for their needs.

Tips for Choosing the Right Void Fill Packaging

Assessing Your Product’s Fragility and Size

The first step in choosing the right void fill packaging is to assess your product’s fragility and size. Fragile items require more cushioning and protection, making options like foam or bubble wrap suitable. On the other hand, for larger, sturdy items, lightweight and cost-effective options like air pillows or paper might suffice.

Understanding Your Shipping Conditions

Consider the conditions your packages will be subjected to during shipping. If your products will be shipped internationally or stored in harsh conditions, you may need a robust void fill solution like foam. For local deliveries with less risk of rough handling, lighter options like air pillows or paper may be adequate.

Consumer Preferences and Perception

It’s also important to consider your customers’ preferences and perceptions. Today’s consumers are increasingly eco-conscious, so using green packaging materials like paper can enhance your brand image. Additionally, consider the unpacking experience for your customers. Some may find packing peanuts messy, while others may appreciate the extra protection provided by bubble wrap or foam.

Proper Usage and Maintenance of Void Fill Packaging

Correct Filling Techniques for Optimal Protection

Using void fill packaging effectively requires the correct filling techniques. Ensure that the void fill material completely fills the empty spaces in your package, but avoid overfilling as it can put unnecessary pressure on your product.

Storing Your Void Fill Materials: Best Practices

Proper storage of your void fill materials can prolong their lifespan and effectiveness. Keep them in a dry, cool place away from direct sunlight. For inflatable options like air pillows, consider investing in on-demand inflation systems to save storage space.

In conclusion, choosing the right void fill packaging involves understanding your product’s needs, shipping conditions, and customer preferences. Proper usage and storage of these materials can further enhance their effectiveness in protecting your products and satisfying your customers.

Regulatory Aspects of Void Fill Packaging

Compliance with Packaging Regulations

Complying with packaging regulations is a crucial aspect of using void fill materials. Different countries and regions have specific rules and standards regarding packaging, which businesses need to adhere to. These may relate to the safety, hygiene, and labeling of packaging materials. For example, certain types of plastic or foam may be prohibited in some regions due to environmental concerns.

Businesses must ensure that their void fill packaging materials meet these regulations to avoid legal issues and potential fines. It’s advisable to consult with a packaging expert or regulatory body to understand these requirements.

Environmental Considerations and Regulations

Environmental sustainability is becoming an increasingly important consideration in packaging. Many regions have regulations aiming to reduce plastic waste and promote the use of eco-friendly packaging materials.

Businesses should consider choosing environmentally friendly void fill options whenever possible. Not only does this help comply with regulations, but it also enhances the company’s reputation among eco-conscious consumers.

In conclusion, understanding and complying with the regulatory aspects of void fill packaging is a key responsibility for businesses. By doing so, they can ensure their packaging practices are legal, sustainable, and well-received by their customers.

Different Brands Offering Void Fill Packaging

Various brands offer a wide range of packaging products, from air pillows and bubble wrap to packing peanuts and paper fill, catering to various industry needs.

It’s important to research these brands and their offerings when choosing your void fill packaging. Consider factors like product quality, cost, environmental impact, and compliance with regulations to make the best choice for your business.

In the next section, we will discuss future trends and innovations in void fill packaging, giving you a glimpse into what the future holds for this essential component of product delivery.

Summary Of Discussion

The Future of Void Fill Packaging: Trends and Innovations

As we look towards the future, several trends and innovations are set to shape the void fill packaging industry. The growing emphasis on sustainability is driving the development of biodegradable and recyclable void fill materials. Innovations like air cushions made from recycled materials or biodegradable packing peanuts are becoming more common.

Furthermore, advancements in technology are leading to smarter packaging solutions. For instance, on-demand inflation systems for air pillows or bubble wrap save storage space and ensure optimal effectiveness of these materials.

Finally, as eCommerce continues to grow, the demand for efficient and protective void fill packaging is set to increase. Businesses will need to adapt to these trends and innovations to stay competitive and meet their customers’ expectations.

Wrapping Up: Making the Best Use of Void Fill Packaging

To wrap up, void fill packaging plays a vital role in ensuring the safe and efficient delivery of products. Whether you’re in the manufacturing/distribution sector, healthcare, education, or building services, understanding and effectively using void fill packaging can significantly enhance your delivery process and customer satisfaction.

By considering factors like your product’s fragility and size, shipping conditions, and customer preferences, you can choose the right void fill solution for your needs. Remember to comply with all relevant regulations and make environmentally friendly choices whenever possible.

At IP Products, we’re here to help you navigate these decisions and provide high-quality void fill solutions tailored to your needs. Reach out to us today to learn more about our offerings and how we can help enhance your product delivery.

Frequently Asked Questions (FAQ)

At IP Products, we offer a wide range of Void Fill Packaging to meet your needs. Browse our collection today and find the perfect Void Fill Packaging for your job. We are dedicated to quality, customer satisfaction, and fast shipping.